Cleanroom Technology: Fundamentals of Design, Testing and Operation

By William Whyte

ISBN: 978-1-917195-15-7; Hardback; 325pp; £85.00

ISBN: 978-1-917195-15-7; e-Book; 325pp; £65.00

Cleanrooms are essential for much of modern industry to provide a clean environment for the manufacture of equipment used in computers, cars, aeroplanes, spacecraft, televisions, etc., as well as the manufacture of medicines, medical devices and foods. Cleanrooms need to be designed, tested and operated in a way that provides the required clean environment, and this book provides the necessary information. This book is written by an international authority with over 50 years’ experience in cleanrooms. It is intended for people who are new to cleanroom technology or wish to update their knowledge. Those who teach cleanroom technology will also find this book very useful. The first two editions of this book were well received but new information has become available and the technology has advanced, and this third edition has been extensively updated.

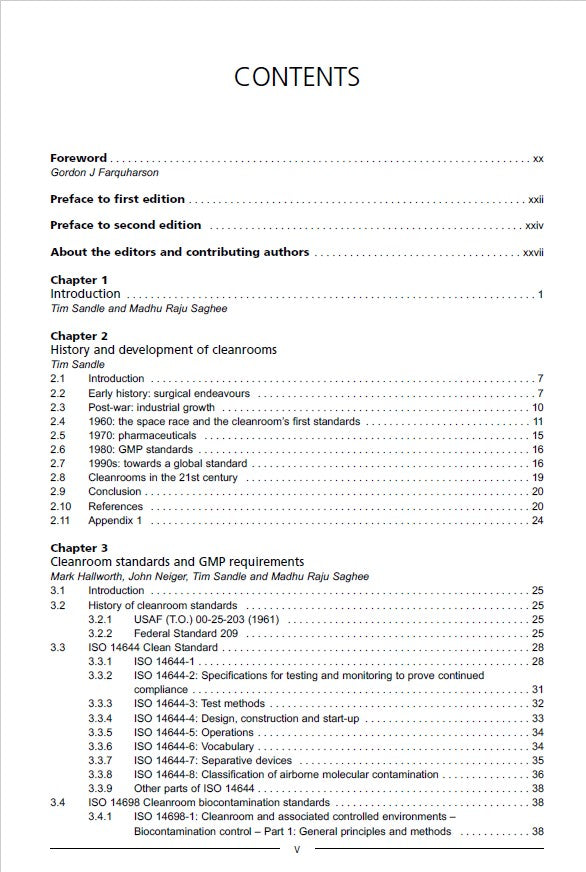

Contents

Chapter 1. Introduction: The need for cleanrooms; types of cleanrooms; what is cleanroom technology?

Chapter 2. History of Cleanrooms: The earliest years; ventilated surgical operating theatres; early industrial cleanrooms; unidirectional airflow cleanrooms.

Chapter 3. Cleanroom Standards, Regulations and Recommended Practices: ISO cleanroom standards; cleanroom classification (ISO 14644-1); control of microbes in cleanrooms; concentrations of other cleanroom contaminants; limits of contamination in pharmaceutical cleanrooms; recommended practices of the IEST.

Chapter 4. Non-Unidirectional Airflow Cleanrooms: Design of non-unidirectional airflow cleanrooms; air conditioning plant and air distribution system; energy reducing measures; high efficiency air filters; airflow and ventilation effectiveness (VE); cleanroom pressurisation; constructional materials and finishes; ancillary cleanrooms.

Chapter 5. Unidirectional Airflow Cleanrooms: Types of UDAF cleanrooms; types of vertical UDAF cleanrooms; computational fluid dynamics (CFD).

Chapter 6. Separative Clean Air Devices and Containment Zones: Open unidirectional airflow workstations; restricted access barrier systems (RABS); mini-environments; isolators; containment rooms and cabinets.

Chapter 7. High Efficiency Air Filters: Construction of high efficiency air filters; filter media; particle removal mechanisms; testing of high efficiency filters; filter housings for high efficiency filters.

Chapter 8. Construction and Clean-build: Constructional materials used in cleanrooms; conventional building methods used in cleanrooms; modular construction; doors, windows, floors, and ceilings; outgassing and electrostatic properties; clean build.

Chapter 9. Cleanroom Testing and Monitoring: Cleanroom test methods; commissioning newly built, or rebuilt, cleanrooms; reverifying and monitoring of cleanrooms.

Chapter 10. Measurement of Air Quantities and Pressure Differences: Instruments for measuring air velocities; measurement of air velocities in UDAF cleanrooms; measurement of air volume supply rates in non-UDAF cleanrooms; differential pressure tests.

Chapter 11. Air Movement between and within Cleanrooms: Containment leak testing; segregation testing; air movement within a cleanroom; measurement of the direction and velocity of air.

Chapter 12. Recovery Performance and Ventilation Effectiveness: Recovery test methods; ventilation effectiveness.

Chapter 13. Filter Installation Leak Testing: Location of leaks in filter installations; methods for locating leaks in filter installations; aerosol test challenges; photometer method for locating leaks; LSAPC method of locating leaks in air filters; repair of leaks.

Chapter 14. Measuring the Concentration of Airborne Particles: Light scattering airborne particle counter (LSAPC); monitoring of airborne particles; measurement of nanoparticles and macroparticles.

Chapter 15. Cleanliness Classification of a Cleanroom: Classifying a cleanroom or clean zone; worked example of ISO 14644-1: 2015 test method.

Chapter 16. Particle Deposition Rate (PDR): What is the particle deposition rate (PDR)?; advantages of the PDR; how PDR is measured; levels of PDR; applications of PDR.

Chapter 17. Microbial Sampling: Microbial sampling of air; microbial air sampling with settle plates; microbial surface sampling; personnel sampling; collection efficiency.

Chapter 18. Operating a Cleanroom: Risk Management and Control of Contamination: Identify sources and routes of contamination; risk assessment of sources of contamination; control and reduction of risk of contamination; establishing a monitoring programme; verification and reappraisal of the CCC system; documentation; staff training.

Chapter 19. Personnel Disciplines: People allowed into cleanrooms; personal items not allowed into a cleanroom; disciplines within cleanrooms; maintenance and service personnel.

Chapter 20. Entry and Exit of Personnel: Prior to arriving at the cleanroom; changing into cleanroom clothing; exit changing procedures. Chapter 21. Items of Equipment used in Cleanrooms: Items prohibited in cleanrooms; machinery and equipment used in cleanrooms; consumables; cleaning of consumables for manufacturing; items supplied from outside manufacturers; wrapping of items.

Chapter 22. Entry of Components, Equipment and Machinery into a Cleanroom: How does a materials transfer area work; transfer of small items; transfer of large items; entry of heavy and bulky items; transfer of materials through hatches and sterilisers.

Chapter 23. Cleanroom Clothing: Sources of contamination from personnel; control of contamination from personnel, types of cleanroom clothing; processing cleanroom clothing; frequency of change; testing of cleanroom clothing for contamination control properties; static dissipative properties of clothing.

Chapter 24. Face Masks, Gloves and Goggles: Cleanroom face masks; cleanroom gloves; cleanroom goggles.

Chapter 25. Cleaning a Cleanroom: Physics of cleaning; implements used to clean cleanrooms; liquids used to clean cleanrooms; how should a cleanroom be cleaned; cleaning programme; cleaning test methods.

About the Author

William (Bill) Whyte is an Honorary Research Fellow at the University of Glasgow, with the useful dual qualifications of a BSc in microbiology, and a DSc in mechanical engineering. He has been carrying out investigations for over 50 years into the design, testing, and operation of cleanrooms and hospital operating rooms. Dr Whyte has published over 150 journal articles on the design of cleanrooms and hospital operating theatres, and the control of contamination within them. He has written the books ‘Cleanroom Technology – Fundamentals of Design, Testing and Operation – Third Edition’; ‘Basic Cleanroom Technology’; ‘Cleanroom Testing and Monitoring’; and edited the book ‘Cleanroom Design’. He is a member of BSI and ISO workgroups that are writing, or have written, ISO cleanroom standards. He has extensive experience as an industrial consultant and presenter of educational courses concerning cleanrooms, and has received numerous awards for his work on cleanroom technology.